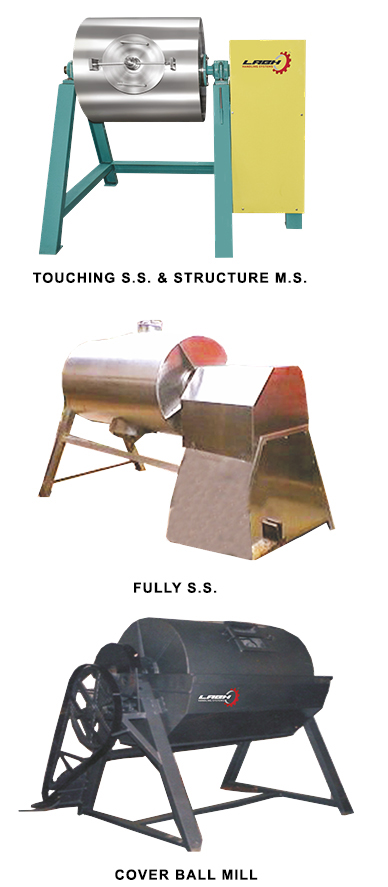

Ball Mill

A ball mill is a sort of grinder used for grinding, mixing and sometimes mixing products used in procedures of mineral dressing, oils, pyrotechnics, ceramics and selective laser sintering. It operates on the basis of effect and attrition: volume decrease is accomplished by effect as the buttons fall off close the shell's bottom.

A Ball Mill for Chemical Powder is a blank cylindrical shell that rotates around its axis. The shell shaft can be either upright or upright at a tiny angle. It's packed with balls partly. The milling medium is the wood (bronze steel), plastic glass, plastic or cotton sticks.

The cylindrical shell's internal layer of Ball Mill for Paint Industries is generally covered with abrasion-resistant materials such as manganese steel or leather covering. Less wear occurs in covered factories of rubber. The mill's span is about the same as its diameter.

The general idea behind the Ball Mill for Cement Industries is an ancient one, but an efficient ball milling machine could not be constructed until the industrial revolution and the advent of steam power. It was reportedly used for pottery milling flint in 1870.

Specification

- Application: 250kg to 5000kg.

- Material: S.S. & M.S.

- Motor: Standard Make

Applications

- Chemical Industries

- Pharmaceutical Industires

- Ayurvedic & Other Industries

Wall Putty Plant Machinery

Wall Putty Plant Machinery

Ribbon

Ribbon Blender

Tilting

TiltingBlender

Ball

BallMill

Vibro

VibroScreen

Screw

ScrewConveyor

Belt

Belt Conveyor

"Z" Type Bucket Elevator

"Z" Type Bucket Elevator

Bucket

Bucket Elevator

Coating

CoatingPan

Wood Fire Water Heater

Wood Fire Water Heater

Storage

StorageTank